Operations Management Exam #1 – Flashcards

Unlock all answers in this set

Unlock answers

question

Organizations Have 3 Basic Functions

answer

Marketing Operations Finance

question

What is Operations?

answer

The part of a business organization that is responsible for producing goods or services Influences all of the rest of the organization The actual doing part of the business process

question

What is Operations Management?

answer

The management of systems or processes that create goods and/or provide services

question

Operations Management affects:

answer

Companies' ability to compete

question

Why study OM?

answer

Every aspect of business affects or is affected by operations There is a significant amount of interaction and collaboration amongst the functional areas

question

The Operations Function

answer

The creation of goods and services through the transformation of inputs into outputs

question

Feedback

answer

measurements taken at various points in the transformation process

question

Control

answer

The comparison of feedback against previously established standards to determine if corrective action is needed.

question

Value Added

answer

value/price of output - cost of input

question

Processes (Managing to Meet Demand)

answer

Operations ; Supply Chains vs Sales and marketing Supply ? Demand is wastefully costly Supply ; Demand causes Opportunity Loss/Customer Dissatisfaction Supply = Demand is Ideal

question

Processes (Variation)

answer

Variations can be disruptive to operations and processes. They may result in additional costs, delays and shortages, poor quality, and inefficient work systems.

question

Manufacturing

answer

goods-oriented (tangible things) physical items that include raw materials, parts, subassemblies, and final products. Automobile Computer Oven Shampoo

question

Service

answer

act-oriented activities that provide some combination of time, location, form or psychological value. Air travel Education Haircut Legal counsel

question

Goods-service Continuum

answer

Products are typically neither purely service- or purely goods-based.

question

Products Package

answer

combinations of goods and services

question

Scope of Operations Management

answer

The operations function includes many interrelated activities such as: Forecasting (we won't cover, but important) Capacity planning Facilities and layout Scheduling Managing inventories Assuring quality Motivating employees Deciding where to locate facilities And more . . .

question

Role of the Operations Manager

answer

The Operations Function consists of all activities directly related to producing goods or providing services. A primary role of the operations manager is to guide the system by decision making. -System Design Decisions -System Operation Decisions

question

System Design Decisions

answer

-Capacity -Facility location -Facility layout -Product and service planning These are typically strategic decisions -usually require long-term commitment of resources -determine parameters of system operation

question

System Operation Decisions

answer

These are generally tactical decisions -Management of personnel -Inventory management and control -Scheduling -Project management -Quality assurance

question

Decision Making

answer

Most operations decisions involve many alternatives that may have different impacts on costs or profits Typical operations decisions include: What: What resources are needed, and in what amounts? When: When will each resource be needed? When should the work be scheduled? When should materials and other supplies be ordered? Where: Where will the work be done? How: How will he product or service be designed? How will the work be done? How will resources be allocated? Who: Who will do the work?

question

Model

answer

an abstraction of reality; a simplified representation of something

question

Types of Models

answer

Physical Models -Look like their real-life counterparts Schematic Models -Graphs, Charts, Blueprints, Drawings, etc. Mathematical Models

question

Common Features of Models

answer

simplifications of real-life phenomena Focus on the most important aspects of the real-life system & omit unimportant details

question

Benefits of Models

answer

Models are generally easier to use and less expensive than dealing with the real system Serve as a consistent tool for evaluation and provide a standardized format for analyzing a problem Require users to organize and sometimes quantify information Increase understanding of the problem Enable managers to analyze "What if?" questions

question

Limitations of Models

answer

Important variables may be missed Quantitative information may be emphasized over qualitative Models may be incorrectly applied and results misinterpreted Nonqualified users may use the model incorrectly

question

Quantitative Methods

answer

A decision making approach that seeks to obtain a mathematically optimal solution -Linear programming -Queuing techniques -Inventory models -Project models -Forecasting techniques -Statistical models

question

Historical Evolution of OM

answer

Industrial Revolution Scientific Management Decision Models and Management Science Influence of Japanese Manufacturers

question

Pre-Industrial Revolution

answer

Craft production - highly skilled workers use simple, flexible tools to produce small quantities of customized goods

question

Industrial Revolution

answer

The Industrial Revolution (late 18th century) -Began in England in the 1770s -Division of labor - Adam Smith, 1776 -Application of the steam engine, 1780s -Cotton Gin and Interchangeable parts - Eli Whitney, 1792 Substituting machine power for human power. Management theory and practice did not advance appreciably during this period

question

Scientific Management (Early 20th century)

answer

"Science of Management" based on observation, measurement, analysis and improvement of work methods, and economic incentives Management is responsible for: -planning, carefully selecting and training workers -finding the best way to perform each job Emphasis was on maximizing output -Ford Model-T, 1908-1927 -Modern-Times, 1936

question

Decision Models & Management Science (Mid 20th century)

answer

OR applications in warfare - Operations Research (OR) Groups Mathematical model for inventory management (F.W. Harris, 1915) Statistical procedures for sampling and quality control (Dodge, Romig & Shewart , 1930s) Statistical sampling theory (Tippett, 1935) Linear programming (George Dantzig , 1947)

question

Influence of Japanese Manufacturers

answer

Late 20th century Refined and developed management practices that increased productivity -Credited for the "quality revolution" -continual improvement -employee empowerment -Lean Operations / Just-in-Time production

question

Key Issues for Operations Managers Today

answer

Economic conditions Innovating Quality problems Management technology The Internet, e-commerce, e-business Supply chain management Risk management Revenue management Competing in a global economy Globalization, Outsourcing Environmental concerns Ethical behavior

question

Customization

answer

requires more resources and effort than more standardized products and services

question

Theory X

answer

Workers do not like work and must be induced to do it

question

Theory Y

answer

Workers enjoy work and are committed to doing it

question

Components of the Supply Chain

answer

Forecasting, purchasing, inventory management, information management, quality assurance, scheduling, production, distribution, delivery, and customer service Doesn't include marketing or finance because those are the two other functions of an organization next to operations

question

Ethics

answer

a standard behavior that guides how we should act in various situations

question

Business Sustainability

answer

refers to economic, environmental, and social sustainability

question

Division of Labor

answer

allows employers to employ less-skilled workers than would have been needed in craft production

question

Which of the following are reasons organizations fail?

answer

Not investing enough in necessary capital or human resources Underestimating the importance of internal communication and cooperation between functional areas Putting too much emphasis on short term financial performance Not focusing enough on process design and improvement Failure to correctly focus on customer wants and needs

question

Three separate, but related concepts that are vitally important to business organizations:

answer

Competitiveness Productivity Strategy

question

Competitiveness

answer

How effectively an organization meets the wants and needs of customers relative to others that offer similar goods or services Organizations compete over: -Price (Cost) -Quality -Response-time -Variety (Flexibility)

question

Quality Based Strategies

answer

may be apart of another strategy

question

3 Basic Business Strategies

answer

Low cost, responsiveness, differentiation

question

Planning and Decision Making

answer

Start at the top with a mission (vision)

question

Order Qualifiers

answer

Characteristics that customers perceive as minimum standards of acceptability for a product or service to be considered as a potential for purchase

question

Order Winners

answer

Characteristics of an organization's goods or services that cause it to be perceived as better than the competition

question

Price, delivery reliability, delivery speed and quality can be qualifiers or order winners

answer

and may change over time.

question

Mission

answer

The reason for an organization's existence that serves as the basis for organizational goals Mission statement -States the purpose of the organization -Answer the question: "What business are we in?"

question

Supply Chain Strategy

answer

should align with overall business strategy

question

Example Strategies an Organization Might Choose From

answer

Low Price Specialization -narrow product lines or limited services Variety -e.g., customization Newness -innovation to create new products or services Service -various aspects of service (e.g., helpful, reliable, etc.) Sustainability -environmentally friendly and energy efficient operations Quality Responsiveness (time-based strategies) -reduction of time needed to complete products or perform services

question

Goals

answer

Provide detail and the scope of the mission Goals can be viewed as organizational destinations The basis for organizational strategies

question

Strategy

answer

A plan for achieving organizational goals Serves as a roadmap for reaching the organizational destinations

question

Strategy Formulation

answer

1. Core Competencies 2. Environmental Scanning (SWOT) 3. Order Qualifiers & Order Winners

question

Core Competencies

answer

The special attributes or abilities that give an organization a competitive edge To be effective core competencies and strategies need to be aligned

question

Environmental Scanning - SWOT

answer

Environmental Scanning is necessary to identify: Internal Factors (Strengths and Weaknesses) External Factors (Opportunities and Threats)

question

Key Internal Factors

answer

Human Resources Skills of workforce, expertise, experience, loyalty to the organization Facilities and equipment Capacities, locations, age, maintenance costs Financial resources Cash flow, access to additional funding, debt, cost of capital Customers Loyalty, wants and needs Products and services Existing, potential for new ones Technology Existing, ability to integrate new and its impact on current and future operations Suppliers Relationships, dependency, quality, flexibility, service Other Labor relations, company image, distribution channels etc.

question

Key External Factors

answer

Economic conditions Health and directions of the economy, inflation, deflation, interest rates, taxes, tariffs. Political conditions Attitude towards business, political stability, wars Legal environment Antitrust laws, regulations, trade restrictions, minimum wages laws, liability laws, labor laws, patents Technology Innovations rate, future process technology, design technology Competition Number and strength of competitors, basis of competitions (price, quality etc.) Markets Size, location, brand loyalty, ease of entry, growth potential, long term stability, demographics.

question

Organizational Strategies

answer

Overall strategies that relate to the entire organization and support the achievement of organizational goals and mission

question

Functional level strategies

answer

Strategies that relate to each of the functional areas and that support achievement of the organizational strategy

question

Operations Strategy

answer

The approach, consistent with organization strategy, that is used to guide the operations function. But... Organization Strategy should take into account the realities of operations strengths and weaknesses

question

Tactics

answer

The methods, actions, or implementations taken to accomplish strategies, which ultimately achieve goals The "how to" part of the process

question

Productivity

answer

A measure of the effective use of resources usually expressed as the ratio of output to input Productivity measures are useful for: -Tracking an operating unit's performance over time -Planning workforce requirements -Scheduling equipment -Financial analysis

question

Why does Productivity Matter?

answer

Higher productivity relative to the competition leads to competitive advantage in the marketplace. High productivity is linked to higher standards of living -; Have more, work less. Manufacturing multiplier (1.6-16): manufacturing has beneficial side effect -; service jobs. Manufacturing incorporates R -; competitive edge.

question

Measures of Productivity

answer

Partial measures: output/(single input) Multi-factor measures: output/(multiple inputs) Total measure: output/(total inputs)

question

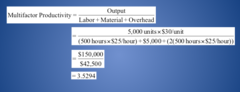

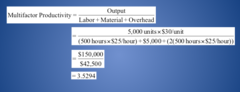

Productivity Calculation Example Units produced: 5,000 Standard price: $30/unit Labor input: 500 hours Cost of labor: $25/hour Cost of materials: $5,000 Cost of overhead: 2x labor cost

answer

larger than 1, but is it good enough? The higher the better

question

Productivity Growth Example

answer

Labor productivity on the ABC assembly line was 25 units per hour in 2009. In 2010, labor productivity was 23 units per hour. What was the productivity growth from 2009 to 2010?

question

Service Sector Productivity

answer

difficult to measure and manage involves intellectual activities has a high degree of variability

question

Factors Affecting Productivity

answer

Methods Quality Capital Technology -INCREASE: Calculators, Computers, Faxes, copiers, Internet search engines, Voice mail, cell phones, email -REDUCE: inflexibility, high costs, mismatched operations, non-work activities Management

question

Improving Productivity

answer

1. Develop productivity measures for all operations 2. Determine critical (bottleneck) operations 3. Develop methods for productivity improvements 4. Establish (reasonable) goals 5. Make it clear that management supports and encourages productivity improvement 6. Measure and publicize improvements 7. Don't confuse productivity with efficiency

question

Efficiency = getting the most out of a fixed set of resources

answer

Productivity = effective use of overall resources (e.g., upgrading equipment)

question

OM Incorporates

answer

suppliers employees distributers retailers

question

What is the first step in creating a new operation

answer

design of product and process to produce it

question

What might cause a business to change?

answer

changes in the market

question

Start of Chapter 4 Notes: Product and Service Design

answer

The essence of an organization is the goods and services it offers Every aspect of the organization is structured around them Product and Service design (or redesign) should be closely tied to an organization's strategy

question

Reasons for Design or Re-Design

answer

Market Opportunities or Threats drive product and service design (or redesign): Economic -Low demand, need to reduce costs, quality problems Social and Demographic -Aging populations, population shifts Political, Liability, or Legal -Regulations, safety issues Competitive -New or changed products and services Cost or Availability -Raw materials, components, labor, energy Technological -Product components, processes

question

Idea Generation Supply-Chain Based

answer

Ideas can come from anywhere in the supply-chain: -Customers -Suppliers -Distributors -Employees

question

Idea Generation Competitor-Based

answer

Studying how a competitor operates and its products and services

question

Reverse engineering

answer

Dismantling and inspecting a competitor's product to discover product improvements

question

Idea Generation Research Based

answer

Research and Development (R&D) -Organized efforts to increase (scientific) knowledge or product innovation Basic research -Objective: advancing the state of knowledge about a subject without any near-term expectation of commercial applications Applied research -Objective: achieving commercial applications Development -Converts the results of applied research into useful commercial applications.

question

Quality Function Deployment

answer

An approach that integrates the "voice of the customer" into product and service development The purpose is to ensure that customer requirements are factored into every aspect of the process

question

Phases in Products Design & Development

answer

1. Feasibility analysis -Demand, development and production cost, potential profit, technical analysis, capacity req., skills needed, fit with mission. 2. Product specifications -What's needed to meet customer wants 3. Process specifications -Weigh alternative processes in terms of cost, resources, profit, quality 4. Prototype development -Few units are made to find problems with the product or process 5. Design review -Changes are made or project is abandoned 6. Market test -Determine customer acceptance. If unsuccessful return to Design-review. 7. Product introduction -promotion 8. Follow-up evaluation -Based on feedback changes may be made.

question

Standardization

answer

Extent to which there is an absence of variety in a product, service, or process Products are made in large quantities of identical items Every unit [customer] processed goes through the same process [receives essentially the same service]

question

Standardization Advantages

answer

Fewer parts to deal with in inventory and in manufacturing Reduced training costs and time More routine purchasing, handling, and inspection procedures Orders fillable from inventory Opportunities for long production runs and automation

question

Standardization Disadvantages

answer

High cost of design changes increases resistance to improvements: designs may be frozen with too many imperfections remaining Decreased variety results in less consumer appeal

question

Mass Customization

answer

A strategy of producing basically standardized goods or services, but incorporating some degree of customization in the final product or service Techniques: -Delayed differentiation -Modular design

question

Delayed Differentiation

answer

The process of producing, but not quite completing, a product until customer preferences are known e.g., Produce a piece of furniture, but do not stain it; the customer will choose the stain or personalized M

question

Modular Design

answer

A form of standardization in which components are grouped into modules that are easily replaced or interchanged e.g., PC Advantages -simplification of manufacturing and assembly -relatively low training costs -easier diagnosis and remedy of failures -easier repair and replacement Disadvantages -Limited number of possible product configurations -Limited ability to repair a faulty module; the entire module must often be scrapped

question

Different phases of a products life cycle require different strategies

answer

in all cases, accurate forecasts of demand and cash flow are critical

question

Designing (products) for Production

answer

1. Concurrent engineering 2. Computer-Assisted Design (CAD) 3. Production requirements 4. Component commonality

question

Concurrent Engineering

answer

Bringing design and manufacturing engineers together early in the design phase -manufacturing personnel, marketing and purchasing personnel in loosely integrated cross-functional teams -Views of suppliers and customers may also be sought The purpose: -achieve product designs that reflect customer wants as well as manufacturing capabilities

question

Computer Aided Design (CAD)

answer

Increases designers' productivity. Directly provides information to manufacturing (dimensions, material - BOM). Perform analysis: engineering ,cost. Shortens time-to-market SolidWorks, AutoCad

question

Production Requirements

answer

Designers must take into account production capabilities -Equipment -Skills -Types of materials -Schedules -Technologies -Special abilities When Opportunities and Capabilities do not match management must consider expanding or changing capabilities. Related concepts: a. Design For Manufacturing (DFM) b. Manufacturability c. Design For Assembly (DFA)

question

DFM and DFA

answer

Design for Manufacturing (DFM) -designing products that are compatible with an organization's abilities Manufacturability -Ease of fabrication and/or assembly -Has important implications for cost, productivity and quality Design for Assembly (DFA) -reducing the number of parts in a product and on assembly methods and sequence.

question

Component Commonality

answer

When products have a high degree of similarity in features and components, a part can be used in multiple products Benefits: -Savings in design time -Standard training for assembly and installation -Opportunities to buy in bulk from suppliers -Commonality of parts for repair -Fewer inventory items must be handled

question

Service Design

answer

Begins with a choice of service strategy, which determines the nature and focus of the service, and the target market Key issues in service design -Degree of variation in service requirements -Degree of customer contact and involvement

question

Differences between Service ; Product Design

answer

1. Services are created and delivered at the same time. Less opportunity to correct errors. Training, process design more important. 2. Services cannot be inventoried -; capacity issues. 3. Services are highly visible to consumers. Importance of process design. 4. Service systems range from those with little or no customer contact (similar to product design) to those that have a very high degree of customer contact 5. Location is often important to service design, with convenience as a major factor. 6. Demand variability - time ; requirements - alternately creates waiting lines or idle service resources. Cost and efficiency perspective vs. customer perspective. -Standardizing at the risk of eliminating features that customers value - reduce customer choices (e.g., cable channels bundle) -Increase flexibility by employing temporary workers

question

Challenges to Service Design

answer

Variability Timing. Services cannot be stored. Balancing supply and demand: possible (e.g., doctor's appointments) impossible (e.g., emergency room). Disney's FastPass Difficult to predict customer requirements especially when there is direct contact with the customer.

question

Service Blueprint

answer

a method to design and analyze a service. Steps: 1. Establish boundaries and decide the level of detail needed. 2. Identify and determine the sequence of customer and service actions and interactions. Picture the service from the customer's perspective. 3. Develop time estimates for each phase of the process, as well as time variability. 4. Identify potential failure points and develop a plan to prevent or minimize them, as well as a response plan.

question

Reliability

answer

The ability of a product, part, or system to perform its intended function under a prescribed set of conditions Reliability is expressed as a probability: -The probability that the product or system will function when activated -The probability that the product or system will function for a given length of time

question

The central feature of Taguchi's approach is parameter design.

answer

It focuses on a much smaller subset of possible production environments of standard design of experiments. This can lead to a near optimal solution.

question

Reliability- When Activated

answer

Finding the probability under the assumption that the system consists of a number of independent components Requires the use of probabilities for independent events Independent event Events whose occurrence or non-occurrence do not influence one another

question

Reliability Rule 1

answer

If two or more events are independent and success is defined as the probability that all of the events occur, then the probability of success is equal to the product of the probabilities of the events (#1 works AND #2 works) Overall reliability is less than the least reliable component. Though individual system components may have high reliabilities, the system's reliability may be considerably lower because all components that are in series must function

question

Redundency

answer

One way to enhance reliability is to utilize redundancy, the use of backup components to increase reliability

question

Rule 2

answer

If two events are independent and success is defined as the probability that at least one of the events will occur, the probability of success is equal to the probability that (either) one occurs (it works) plus (OR) 1.00 minus that probability (it fails...) multiplied by the probability the other occurs

question

Rule 3

answer

If two or more events are involved and success is defined as the probability that at least one of them occurs, the probability of success is 1 - P(all fail). 1 - (#1 fails AND #2 fails AND #3 fails) Can also be calculated by using Rule 2 multiple times.

question

Reliability Over Time

answer

Reliabilities are determined relative to a specified length of time.

question

Improving Reliability

answer

Component design Redundancy/backups System design Production/assembly techniques Testing Preventive maintenance procedures User education