FSN 334 Food Packaging Midterm 1

Unlock all answers in this set

Unlock answersquestion

Protection

answer

The Package must protect the food throughout its shelf

question

Four Package Functions of Packaging

answer

Containment Convenience Communication Protection

question

Containment

answer

Basic function of the package - helps portioning, sanitary handling, storage, movement, transportation, merchandising and purchasing.

question

Convenience

answer

The aspect of the package that makes it user-friendly, ergonomic, or a better fit into ones modern lifestyle.

question

Communication

answer

The package communicated as a silent salesaman with marketing information through design, graphics, brand identity, etc. Also communicates nutritional information, ingredients, serving suggestions, preparation instructions and manufacture/distributor info

question

Food Scientists and technologists on this function

answer

Protection

question

Protection

answer

Package must protect the food throughout its shelf life. Also can be stored at room temperature, frozen or refrigerated temperature. Must protect the food from ambient, physical and human environment.

question

In order to study the food pack it is helpful to organize it this way:

answer

Divide it into Primary, Secondary, Tertiary, Quaternary packages

question

Primary Package

answer

In direct contact with the contain product. Provides the initial and (usually) most protective barrier. Prevents contamination, and acts as a moisture barrier (Think of plastic cereal bag)

question

Secondary Package

answer

Provides rigidity, protects product, communicates and contains a number of primary packages (Think of cereal box)

question

Tertiary Package

answer

Is the shipping container - groups packages for handling, protects during shipping. Contains a number of secondary packages (pallets, corrugated cases)

question

Quaternary Package

answer

Holds the tertiary package. Normally metal container which can hold many pallets and can be transferred to or from ships, etc.

question

Why is it important to consider packaging environment when creating the package?

answer

Package must be able to perform its function in all three environments. Failure to do so will result in poorly designed packages, increased costs, consumer complaints and rejection of the product by the consumer.

question

3 Types of Packaging Environments: Physical, Ambient and Human.

answer

Physical, Ambient and Human.

question

Packaging Environment: Physical

answer

Environment that physical damages can occur to the product. Ie. shocks from drops, falls and bumps, damage during transportation mode, etc.

question

Packaging Environment: Ambient

answer

Environment that surrounds the package. Damage to the product can be caused as light (UV radiation), gases (oxygen), temperature, microorganisms, microorganisms, etc

question

Packaging Environment: Human

answer

Packages interact with people and designing packages for this environment requires knowledge of the variability of consumers capability. Messages need to be clearly communicated to consumers and packages must contain information required by law.

question

The function/environments grid

answer

The functions of packages and the environments where the package has to perform can be laid out in a two way matrix or grid. Anything done in packaging can be classified and located in 1 or more of the 12 cells.

question

Pulp

answer

Fibrous raw material used to make paper based packaging. Obtained from plant fiber so is a renewable resource

question

Three main constituents of pulp

answer

Cellulose, hemicellulose and lignin

question

Fiber sources:

answer

Spruce fiber, birch fiber, pine fiber and a mix of all 3

question

Main sources of fiber are:

answer

Hardwood (poplar, aspen and maple) and Softwood (pine, spruce, Hemlock)

question

Most important fiber characteristic is:

answer

Length

question

Importance of fiber length in paper

answer

Long fiber - higher tensil, tear fold and puncture strength Short fibers - smooth surface texture

question

Purpose of Pulping

answer

To seperate fibers without damaging them so that they can be formed into a sheet of paper

question

Problem with Pulping

answer

Presence of lignin which must be softened or dissolved to free individual fibers. (Pulps that retain most of the wood lignin consists of stiff fibers that don't produce sttrong paper)

question

Removal of lignin is done with:

answer

Chemicals, mechanical mean, combined methods

question

Paper manufacturing steps

answer

Beating - improve of pulp strength paper making - depositing a very dilute suspension to reduce moisture content to4-10% by draining, pressing and drying Converting: helps to further smoothen and make uniform thickness. Determines finish

question

Bleached Paper

answer

Good for appearance and printing quality. Ie sugar

question

Parchment Paper

answer

Treated with sulfuric acid which makes it plastic like/high strength ie bucher shop

question

Grease Proof Paper

answer

Made from densely packed chemical pulp. Ie cookies, back goods, candy, snacks, bar, etc.

question

Glassline paper

answer

grease proof for butter and margarine's use

question

Waxed Paper `

answer

Provides a barrier againt penetration of liquuis and barrier

question

Paperboard

answer

Termed board when it grammage exceeds 224 g/m2 weight or .012 inches

question

Food Board

answer

A typeof baberboard made from pleached sulfate paper board which has a nice appearance and strength. ie for scored cartrons like ceral boxes, beverage baskets (ie 6-pack) etc.

question

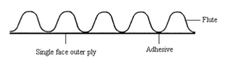

Liner board Versus medium board

answer

Liner board is used for the face of the corrugated board where as medium board is used for the fluted core of the corrugated board

question

Chipboard

answer

A type of paper board made from recycled paper. Gray in color (blemishes) poor quality, used for partitions between glass containers or molded pulp such as for egg cartons, etc.

question

TPS or ETP

answer

Tin Plated Steel or electrolyte tinplate steel strip is cleaned and coated with tin layer

question

TFS/ECCS

answer

Tin Free Steel (TFS) is Electrolytic Chrome Coated Steel (ECCS) (less expensive than ETP)

question

3 common metals in Food Packaging

answer

Tin Plated Steel, Tin Free Steel, Aluminum

question

In general steel based material is used for (name 3):

answer

Cans to be retorted, Closure for glass packages, bulk drum

question

Steel - Advantages in Packaging:

answer

Excellent Barrier Thermal Conductivity Thermal Stability Physical strength Good surface for printing Physical Strength Recyclable

question

Steel - Disadvantages in Packaging

answer

Weight (heavy) High Cost (Dependent on metal) The need for enamels because of corrosion (rust)

question

Metal corrosion Issue Factors inherent with Foods

answer

Acidity pH Sulfur Components Nitrates Phosphates Plant Pigments Synthetic colorings Copper

question

Metal corrosion Issue factors: Effects of processing and storage

answer

Oxygen Thermal Processing Storage temperature

question

Cans's coated/enameled/lacquered both internally or externally to:

answer

Prevent corrosion, prevent interaction of the can with food product and aid in handling/decorating.

question

Acrylics Applications

answer

Steel can coating for exteriors where a clean, white look is desired. Expensive, takes heat processing well. Ie Single serve pudding

question

Vinyl Applications

answer

Steel can coating for beer, soft drinks and tomatoes juices. Good because it's resistant to acid and alkaline product. Not suitable for retorted food.

question

CMI

answer

The Can Manufacturers Institute - trade association of metal and composite can manufacturing industry and its suppliers in the US

question

Aluminum

answer

Versatility material Impart strength, improve formality characteristics and influence corrosion characteristics

question

Aluminum Advantages

answer

Provide excellent barrier properties Good mechanical strength Low toxicity Cheap to produce in large quantities Can be heat treated, suitable for sterile porduct Can be hermetically sealed Can be easily recycled Ideal for surface decorating and lacquering

question

Aluminum Application and Advantages

answer

Soft, very light weight, inexpensive Used for Beverage containers, lamination of paperboard or plastics, foil for candy wrapping.

question

Aluminum - disadvantages

answer

Shipping an empty can takes up a lot of space Can't maximize shelf space Corrosion issues during storage if it's not lacquered or coated. Limited sizes and shapes of cans Not suitable for microwave oven use

question

Plastic definition

answer

Group of synthetic resins or other substances that be folded into any form

question

Americans use _________ every hour. Most are thrown away __ Percent of plastic packaging is used for food products every year

answer

2,500,000 66%

question

Thermo Plasticity:

answer

Melts and solidifies repeatedly without altering property or performance. Advantage of plastics

question

Advantages of plastic:

answer

Low cost/weight, thermo plasticity, almost ultd. properties and performance, design freedom, no corrosion, easy coloring, good barrier

question

Plastic Disadvantages

answer

Low heat resistance (melts), poor gas barrier, potential for cracking, environmental concerns (ie BPA chemical)

question

Properties of Polythylene:

answer

Stiffness, strength/tough, low cost, easy to form, resistant to chemicals, permeable to gas, easy to process, versatile

question

Polyethylene (PE) is used extensively because it's (Note:Surpasses all plastics in quantity produced)

answer

Economical and versatile.

question

HDPE: Acronym for _______ Recycle Number _

answer

High Density Polyethylene (PE Family) Recycle number 2 Good moisture barrier, moderate grease barrier, poor gas and flavor barrier, density of more than 0.94 g/cc Used for grocery bags, yogurt, sour cream, margarin tubs, foo bottles (milk jugs) bottle caps, etc.

question

LDPE: Acronym for _______ Recycle Number _

answer

Low Density Polyethylene (PE family) Recycle number 4 Similar properties to HDPE but more clear, more flexible at low temperatures, and has a good heat property at 110 degrees celsius Used for bread bags, squeeze bottles, stretch/shrink wrap, trash bags, snap on closure for tubs, etc.

question

LLDPE: Acronym for _______ Used for:

answer

Linear Low Density Polyethylene Used more for squeeze bottles and stretch/shrink wrap

question

(PS): 1.Acronym for _______ 2.Recycle Number _ 3.Also known as

answer

Polystyrene or Expanded PS (EPS) Recycle Number 6 AKA Sytrofoam

question

Good Properties of PS Disadvantages

answer

Versatile (rigid or foamed), Insulation, ease of process, low cost, clarity PS is brittle (poor impact strength) Note- Can improve by blending with polybutadiene

question

Is Polystyrene suitable for protecting most foods? Why or why not?

answer

No, it's a poor gas and water barrier. However, the permeability makes it suitable for breathable wrap for fresh produce

question

PS applications in it's clear form: PS as a white material: EPS (Expanded PS):

answer

Beverage cups and windowed cartons Single serve portions of jams and coffee creamers Expanded by pentane gas as a blowing agent, has excellent thermal insulating properties which make it great for hot beverage cups, food stock trays, meat and poultry trays

question

PP Acronym for Recycled Number___ High or low density? Excellent for _____ resistance

answer

Polypropylene 5 Low density (.9-.915 and lighter than water... floats) Chemical

question

Advantages of Polypropylene

answer

Strength/toughness, resistant to chemical, heat, oil and grease. Barrier to moisture, low cost, versatile, and easy to process. Excellent moisture barrier, good optical quality, fair gas barrier, brittle at low temps, has a good heat seal

question

PP is similar to PE except for the fact that

answer

PP is stiffer and contains a higher softening temperature (reduced deformation at elevated temperatures)

question

Polypropylene Application

answer

Threaded closures, laminate layer in form fill seal snack food applications, candy bar wraps, microwaveable containers, butter and yogurt tubs (PE closures)

question

PET Acronym for Recycle Number___ Excellent for: Heat Seal Property?

answer

Poly Ethylene Terephthalate (PET) Recycle Number 1 PET has a very high melting point Excellent grease and oil barrier, low gas and moisture permeability, good printing characteristics. No heat seal property

question

PET applications:

answer

Replaced glass in many water, oil alcohol and carbonated soft drink bottle (ie smart water) As a film, is used for cheese and meat packaging CPET (crystalline PET) is used for dual ovenable trays

question

PCV Acronym for Recycle Number___ Disadvantages: Advantages:

answer

Polyvinyle Chloride Recycle number 3 Unstable and decomposes easily - limited use in food packaging because of potential migration Use as a tamper evident band or heat shrink label stock Low permeability to water vapor, gases, flavors. Good grease and oil resistance properties

question

EVOH

answer

Ethylene Vinyl Alcohol Highest oxygen barrier Not stable when in contact with water Used as a middle laminate to improve oxygen and flavor barrier properties

question

PA

answer

Acronym for Polyamid AKA Nylon Good oil and grease resistance, high temperature stability, good gas oxygen and flavor barrier, resistant to abrasion impact and puncturing, Not heat sealable, not water vapor barrier Used for meat and cheese vacuum packaging, cook in the bag applications, etc.

question

Filler machines

answer

Measure out a specific quantity of food product and place that metered quantity of a food in a package. Versatile in applications

question

2 categories of fillers

answer

Volumetric fillers and weight fillers

question

4 categories of volumetric fillers:

answer

Piston filler, diaphragm filler, time flow filler, auger filler,

question

Weight filler

answer

Net weight filler Gross weight filler

question

Piston Filler: Action of a single piston steps:

answer

1. Intake stoke - piston draws product out of supply tank and into measuring chamber 2. Following stroke - valve leading to the container is opened, valve leading to supply chamber is closed, causing product flows out of chamber into container. 3. Container is conveyed away and replaced by an empty container

question

How does a Volumetric/Piston Filler control volume?

answer

By length of stroke and diameter of chamber

question

Advantages of a Piston Filler:

answer

Versatile - can handle thick and thin products, even products with particulates or chunks

question

Diaphragm Filler

answer

Similar in principle with piston filler but instead of a rigid piston, diaphragm flexible

question

Steps for pumping

answer

1. Cycle Starts - valve at bottom of supply tank. Valve to empty container closed 2. Air pressure into tank forces the out into the measuring chamber (Top of the chamber is formed by the diaphragm with the plunger above) 3. Product flows into chamber. Diaphragm lifted 4. Valves and air pressure applied to plunger - forces product out and into container

question

Timed Flow Filler

answer

Designed for free flowing liquids like milk, pancake syrup, cooking oil, alcoholic beverage, Quantity depends on the time that the product flows Includes a supply tank and a pump, timer and pipes

question

Auger Filler

answer

Used for dry products and thick pastes. The product is held in a cone shaped bin and conveyed out through an opening at the bottom by an auger

question

Auger Filler: Volume of product is directly related to

answer

Number of degrees the auger rotates Control can be based on time or degrees of rotation

question

Weight Filler

answer

For products with no uniform density that require more accurate metering than can be possible with volume filling

question

2 main categories of weight fillers

answer

Gross weight filler and net weight filler

question

Net weight filler

answer

Measures out the desired weight of product before it enters the containers. Scale measures weight of product, when the weight in the hopper reached, the feeder stops and hopper discharges product into a funnel.

question

Gross weight filling

answer

Measure the weight of the product and the package Before filling, samples of packages are weighed and average is calculated. Scale is preset with the sum of the desired product weight and the averaged weight of the container. Product metered directly into container

question

2 Types of set up of the fillers in production line:

answer

In line Rotary

question

Arrangement of the Fillers: In-Line

answer

Mostly used for liquids and paste into metal cans and glass bottles Must have at least one filling head, but often has 4 Empty containers conveyed in single file by in feed conveyer. Containers held in position by rear block until all are filled. Filled containers move forward, rear block moves and then new containers move forward and the rear block is placed back.

question

Arrangement of the fillers: Rotary Fillers

answer

Remove empty containers from the in feed conveyer and place them on the rotating turret of the filler, filled as they travel around the outside of the filler. Once filled, placed onto the out feed conveyor. Fast system

question

Capping Equipment - 2 types:

answer

In line and rotary Induction sealing

question

In Line Capper

answer

Set of spinning disks that tighten the cap to the desired application torque FSN pilot plant - series of belt that tightens the cap in a steam chamber. Steam sanitizers and better seals the cap.

question

Rotary capper

answer

Higher speed than inline capper, similar arrangement to rotary filler, as capper rotates the caps are applied and tightened

question

Induction Cap Sealing

answer

Process in which the aluminum foil disc is sealed to the mouth of a bottle in order to ensure the safety of the product inside. Foil Disc inside the cap, Bottle passes under the induction sealer after the filling and capping process. Used for Plastic Bottles

question

Indiction sealing is good because:

answer

Leak proof sealing (eliminates product recall costs due to leakages i container), increase shelf life, it's tamper evident, enhanced customer care

question

Form Fill Seal Machines

answer

Machines that form, fill and seal package on the same machine - used for wide range of products including dry powders and liquids

question

Form Fill Seal (FFS) Machines perform 3 operations:

answer

Form the package, fill the package, seal the package

question

3 types of form-fill-seal machines:

answer

Vertical FFS Horizontal FFS Thermo FFS

question

Vertical FFS

answer

Product flows directly down the machine as the forming filling and sealing operations are performed. Dry Cereal, granular sugar, cake mixes.

question

Horizontal FFS

answer

Flat web of material is unwound from a roll. Filling is down in rapid flow filler followed by slower one.

question

Thermo FFS

answer

Used for meat, pasta products. 2 films to make packages. One plastic web is thermoformed into a tray and the other is heat sealed onto the tray to form the cover One plastic web is thermoformed into a tray and the other is heat sealed onto the tray to form the cover Bottom material unrolls and passes through heaters to soften the plastic web Then the soften web goes through the forming section where combination of pressure and vacuum pulls the plastic into the shape of a tray

question

2 general categories for package testing and evaluation

answer

Physical strength nd protection

question

Who's in charge of what in terms of Packaging Evaluation?

answer

Food process is given specs on physical properties of packaging, by the packaging supplier

question

What is the responsibility of the food company in terms of Packaging Evaluation

answer

Evaluating the ability of the primary package to protect the food within, for the the expected shelf life

question

ASTM

answer

American Society for Testing and Materials Compiles testing protocols for many material. Focuses on physical properties pf package material

question

Package Evaluation - Physical Strength

answer

Testing protocols available for primary, secondary, tertiary, etc. packaging They also help assess the ability of the final package to protect the food in the physical environment

question

TAPPI

answer

Technical Association of the Pulp and Paper Industry

question

Paper evaluation

answer

Moisture content: Paper is hygroscopic so its moisture content varies wit the ambient relative humidity International testing standard for any paper quality calls for testing conditions of 23 degrees C and 50% RH

question

Caliper

answer

Thickness measured by a micrometer

question

Basis Weight

answer

Weight of a given amount of paper

question

Brightness

answer

Amount of light reflected off paper

question

Moisture pick up

answer

Amount of water at a given temperature soaked into a given weight of paper after a given time

question

Bursting Strength Test

answer

Mullen, tests drop resistance. Strength test

question

Edge crush Test

answer

Tests rigidity, stacking strength. Strength test

question

Flat Crush

answer

Tests compression resistance. Strength test

question

Puncture

answer

Tests resistance to puncturing and shocks. Strength test

question

Adhesion Test

answer

Adhesion of paper plies and of liners to fluting

question

Moisture Resistance

answer

Cobb; water absorption test

question

Two factors involved in empty glass containers evaluations are:

answer

1. Potential for breakage and 2. Container and finish dimensions

question

Most critical Evaluation of metal cans relevant to food protection is the double seam inspections:

answer

Visual: Pull cans from the seamer and look for deforms (more frequent test) Tear-down: Pull cans and tear them apart to measure certain parameters - less frequent

question

Seam thickness

answer

Thickness of finished seam. Can will have a particular range of seam thickness which will be an indicator of the overall pressure applied during the seaming operation

question

Plastic Evaluation Tests - Tensile strength and stretch/elongation test

answer

Tests behavior under stress.

question

Tensile Strength

answer

The tensile strength is the stress needed to break the sample expressed in pascals or psi Elongation

question

Elongation:

answer

Elongation to break is the strain on a sample when in break. Normally expressed in %

question

The 3 Factors controlling shelf life:

answer

Intrinsic Extrinsic Packaging properties *Packaging is at the center of all shelf-life studies and its role is of paramount importance

question

Intrinsic

answer

Food product characteristics. Ie pH, water activity, enzymes, microorganisms, concentration of reactive compounds

question

Extrinsic

answer

The environment during distribution and storage Packaging properties.

question

Factors controlling shelf life Environment during distribution and storage

answer

Climatic - mass (exchange of moisture and gases) and heat transfer (temperature fluctuation) Physical - pallet stacking pattern

question

Gas of Major importance in terms of shelf life and packaging? Why?

answer

Oxygen Because it has a crucial role in many reactions which affects the shelf life of foods such as microbial growth, color change, etc.

question

Packaging can control variables with respect to oxygen and these can have different effects on the rates of oxidation in food:

answer

1. Total amount of Oxygen present 2. Concentration of Oxygen in the foods

question

OTR

answer

Oxygen Transmission Rate - steady state at which oxygenase can permeate through a film. Expressed as a volume of oxygen that penetrate a given area in one day period at 73 degrees F and 0% RH. The higher the cc/m2/24hrs, higher transmitter of O2. The lower cc/m2/24 hrs, the higher barrier of O2

question

Shelf Life study:

answer

Objective means for determining how long a product can reasonably be expected to keep without an appreciable change in quality, safety and characteristics. Shelf life eval and management is essential part of food quality management and overall Quality Management System through the entire chain value.

question

What defines shelf life?

answer

Sensory, nutritional and toxicological characteristics

question

Shelf Life Direct Method:

answer

Storing Product Under selected conditions for a period of time longer than the expected shelf life and checking it at regular intervals to see when it begins to spoil

question

Indirect Method

answer

Predict the shelf life without running a full length storage trial Are useful for products with longer shelf life Accelerated shelf life testing or predictive models

question

Accelerated shelf-life testing (ASLT)

answer

The trial period is shortened by deliberately increasing the rate of deterioration. This is usually done by increasing storage temperature. Chemicals kinetics can be applied o quantify the effects of extrinsic factors on the rate of deterioration reactions in foods.

question

Predictive Models

answer

Using information available from a database to predict bacterial growth under defined conditions, which is then used to calculate the shelf life of a food.